Injection Moulding

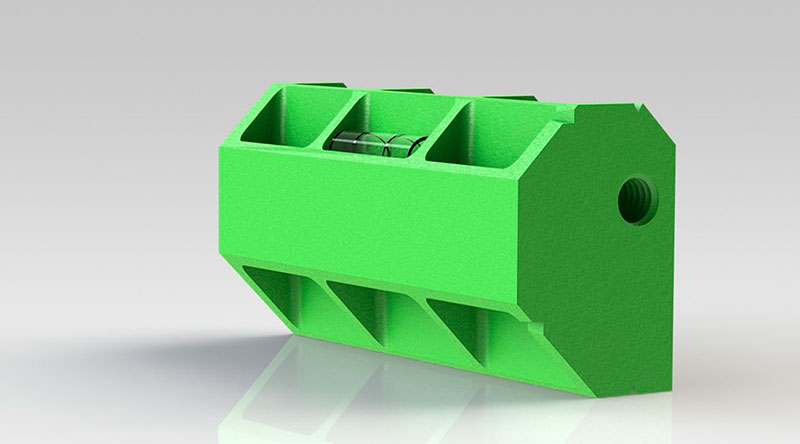

Injection moulding is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould maker or toolmaker from metal, either steel or aluminium.

Injection moulding is widely used for manufacturing a variety of parts, from smallest components to entire body panels of cars Parts to be injection moulded must be very carefully designed to facilitate the moulding process; the material used for the part, the desired shape and features of the part, the material of the mould, and the properties of the moulding machine must all be taken into account.